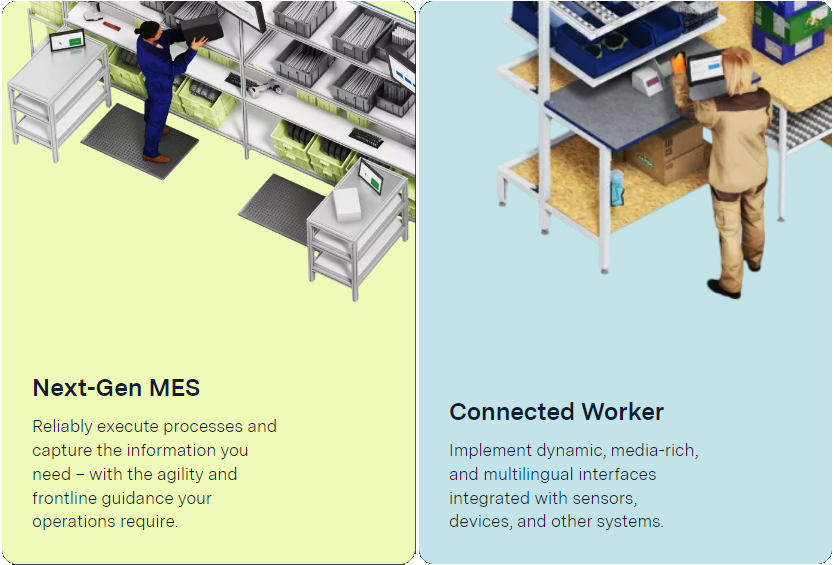

Tulip offers a wide range of solutions that improve manufacturing operations. With next-gen MES, connected workforce integration, electronic records management, and visual quality inspection, Tulip drives efficiency and enhances overall quality.

Discover how Tulip’s next-gen MES, connected workforce integration, electronic records management, and visual quality inspection optimize manufacturing operations. Streamline processes, ensure compliance, and drive efficiency with Tulip’s solutions.

Tulip offers a wide range of solutions that improve manufacturing operations. With next-gen MES, connected workforce integration, electronic records management, and visual quality inspection, Tulip drives efficiency and enhances overall quality.

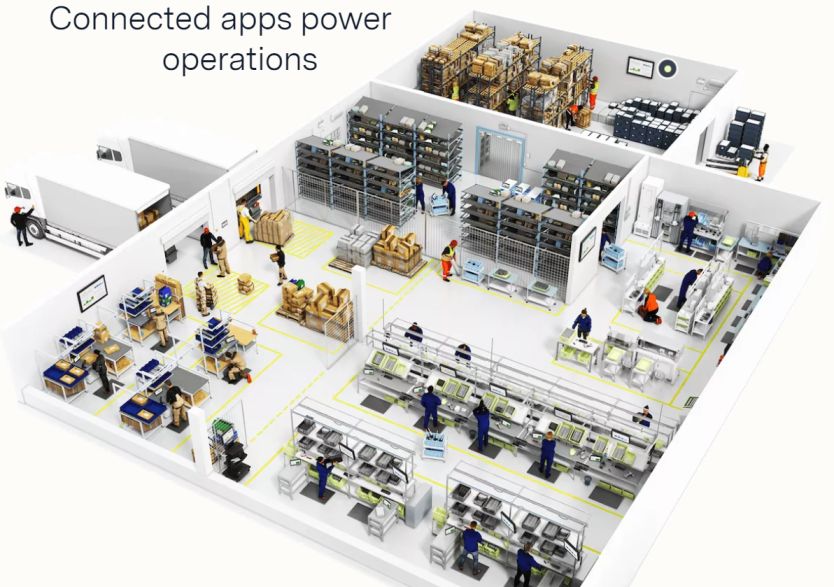

Tulip’s digital solutions provide manufacturers with powerful tools to streamline processes and maximize efficiency. By digitizing workflows, Tulip helps automate repetitive tasks, eliminate manual errors, and accelerate production cycles. With its user-friendly interface and real-time analytics, Tulip enables manufacturers to identify bottlenecks, optimize resource allocation, and better decisions for continuous process improvement.

Tulip offers a next-gen MES platform that integrates seamlessly with connected workforce solutions, electronic records management (eBR/eDHR), and visual quality inspection. This powerful combination streamlines manufacturing operations by providing frontline guidance, real-time data exchange, compliance acceleration, and ML-powered defect detection.

In conclusion, Tulip offers a range of solutions that significantly improve manufacturing operations. By effectively managing material systems replenishment through Kanban loops, providing real-time visibility into work order status, visualizing production progress, guiding operators with dynamic workflows, and streamlining workflows while connecting systems, Tulip empowers manufacturers to achieve operational excellence.